Innovative Solution for Innovative Products

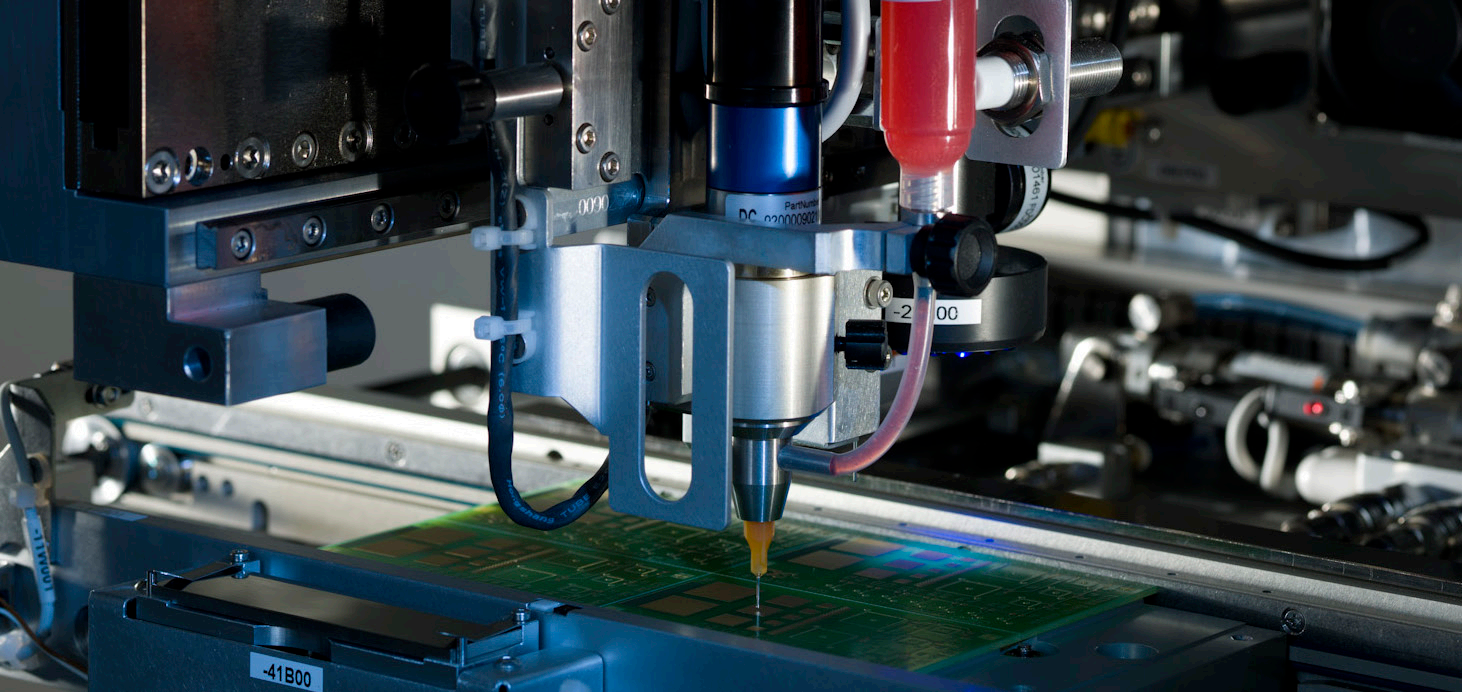

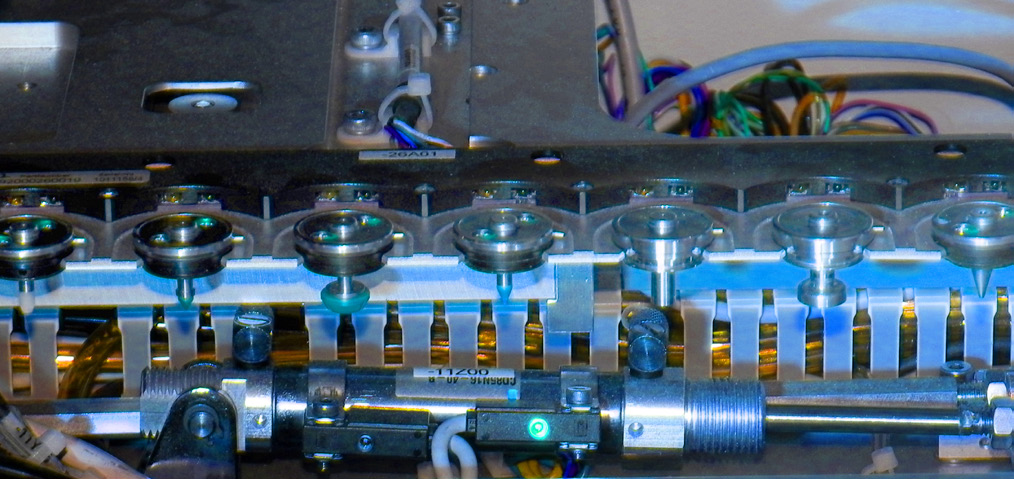

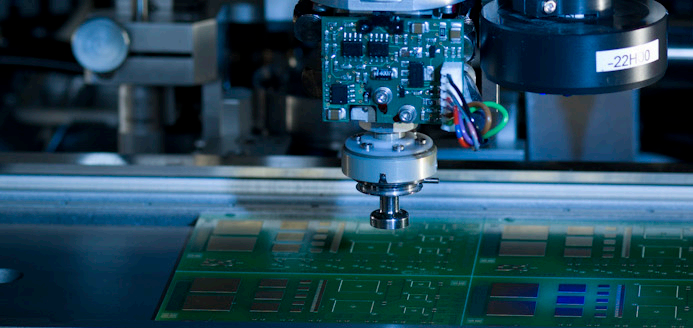

The 2200 evoplus die bonder for Multi Module Attch assembles all kinds of technologies on a tried-and-tested platform, enhanced with key features for higher bonding accuracy and lower cost-of-ownership.

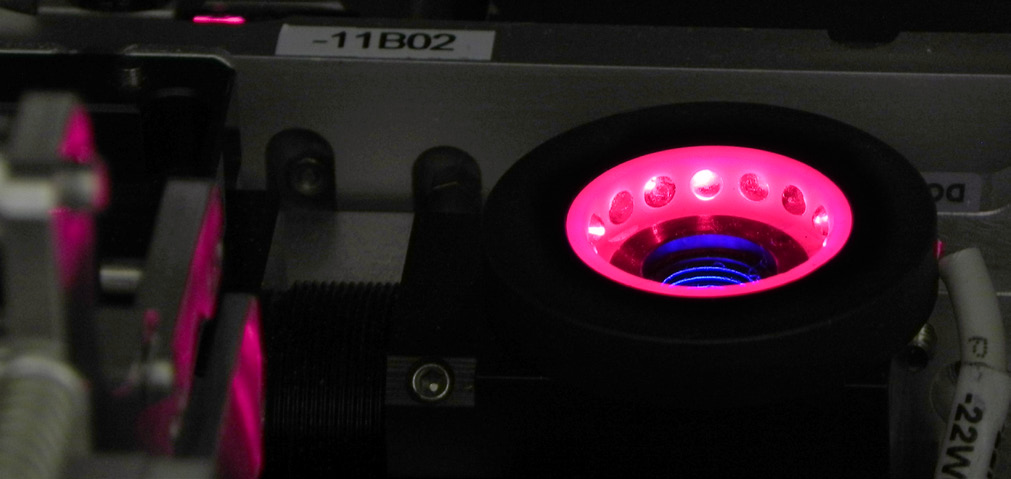

Besides unbeaten flexibility and full customization possibilities, this evolutionary machine offers higher accuracy with long-term stability using a new camera system and thermal compensation algorithm, higher speed through a new image processing unit, and improved cleanroom capabilities.